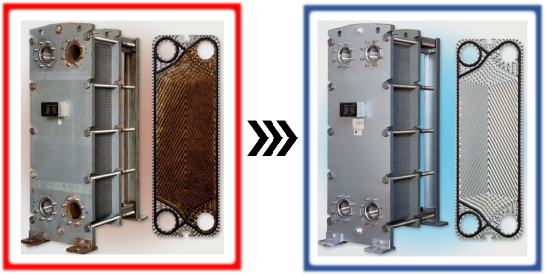

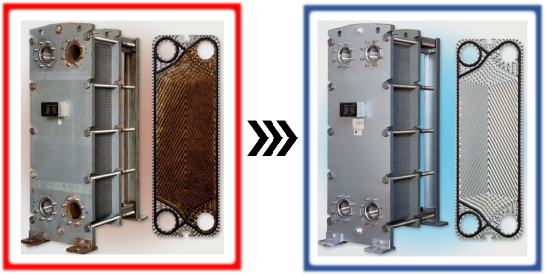

Most mechanical equipment requires a certain degree of servicing and maintenance after long period of usage. Plate heat exchanger is also one of the mechanical equipment which requires servicing & maintaining at a yearly basis. Why? When plate heat exchanger after a long period of usage, its performance will decrease. This is due to the fouling and coagulation happening on the heat exchanger plate surface. When there is fouling on the plate, the heat transfer capability will start to decrease which will affect the performance.

PHE is design to be maintenance friendly. You would just need to unlock the tightening bolts and move the e-frame, then the plates can be dismantled for cleaning.

Alternatively, you can also contact our specialist to conduct your regular preventive maintenance.

Prevent scaling on the plate surface.

Maintaining the energy efficiency of your process line.

Required output temperature can be maintained.

Avoid unexpected failure of heat exchanger which causes shutdown

Leaking of plate pack can be caused by few main factors. The most common one will be the plate pack is not tighten properly. But sometimes, gaskets deteriorated or damage can also caused leaking of plate pack. Moreover, corrosion happened at the plate gasket groove or double sea area will also caused leaking. Furthermore, wrong plate arrangement, or contamination on the gasket seal surface can also contribute to leaking. Lastly, overlapping or twisting of gaskets from groove is also one of the factor.

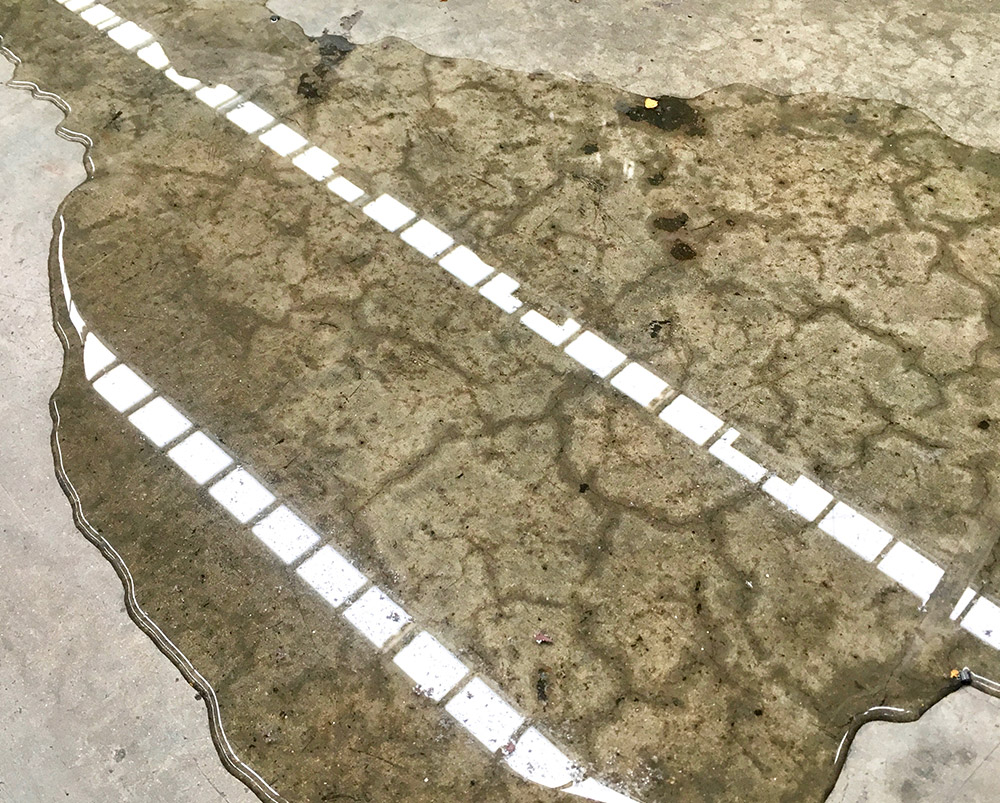

One of the cause for fluid intermixed happened in a heat exchanger is due to its plate corrosion. When corrosion happened, the plate surface of the heat exchanger will be corroded, at some point crackline will form which caused intermixing of fluids.

The overall heat transfer coefficeint of plate heat exchanger is decreased due to the fouling or scalling forming on the plate surface which create unwanted layer that act as a barrier which then decrease the rate of heat transfer.

The reduce in flow rate of a heat exchanger could happen when the port holes are clogged and scale happening on the plate surface.

Hisaka Professional Service Team are able to provide you a complete servicing package for all your plate heat exchanger to maintain the performance of your plate heat exchanger.

HISAKA service team is always here to help you get the best performance on your HISAKA's heat exchanger. We work with you in every way to maintain the performance of your heat exchanger over time. Feel free to pre-book our service team now and get your HISAKA's heat exchanger back into pristine condition.

We are always committed to make your maintenance work easier. With this new QR code sticker, you just need to scan and submit us the details. In 24 hours, Hisaka after sales team will respond to you.

Contact us now to get FREE QR STICKER for your Plate Heat Exchanger!