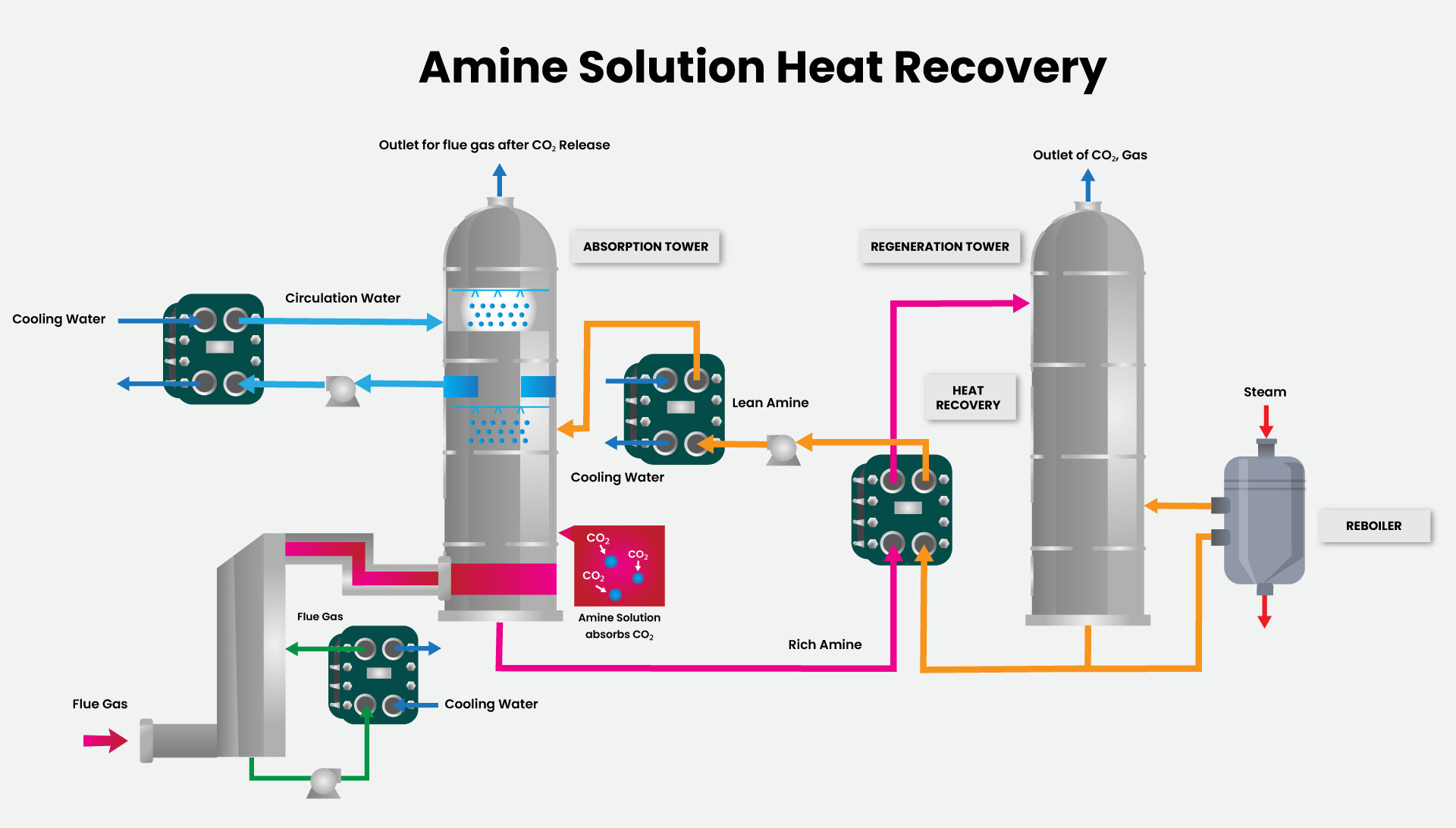

Process Flow Diagram

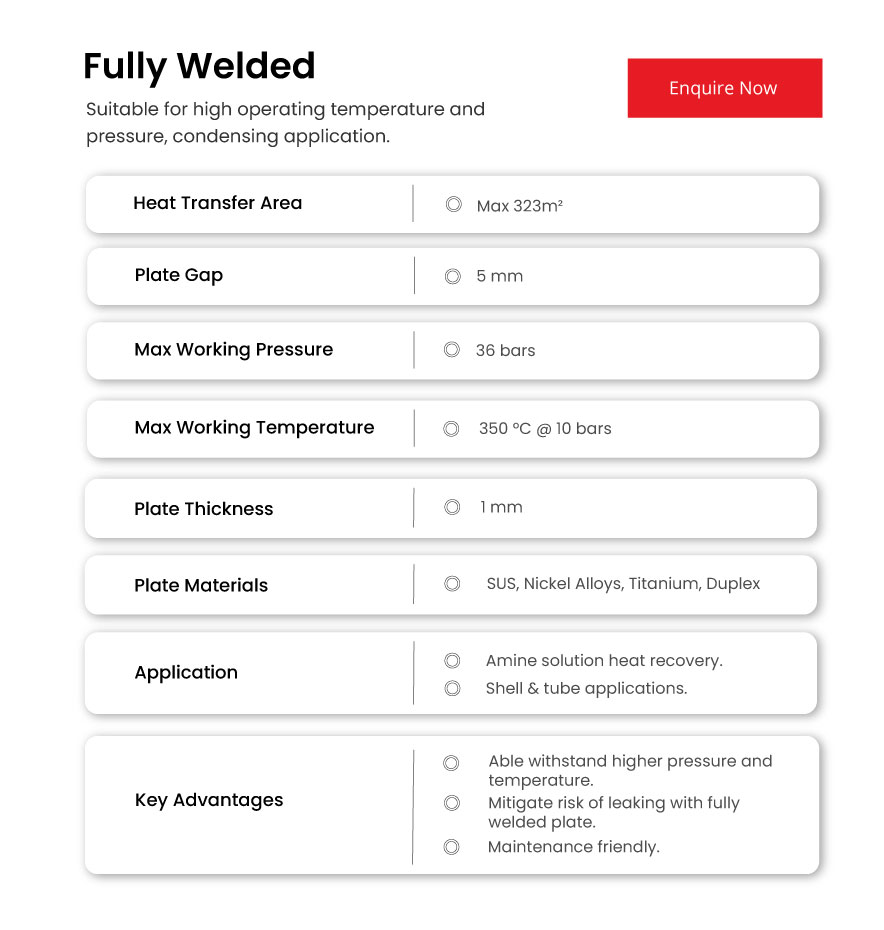

Amine Solution Heat Recovery

One of the best practices to recover Carbon Dioxide is using Amine solution. Lean amine is used to absorb Carbon Dioxide by contacting with flue gas in the absorption tower.

After absorbing Carbon Dioxide from the flue gas, lean amine becomes rich amine which needs to be heated before feeding into the regeneration tower to release Carbon Dioxide. In this process, steam is normally used to heat the rich amine. By incorporating a heat exchanger as a heat recovery unit, one can reduce the steam volume to heat the rich amine and achieve up to 85% heat recovery.

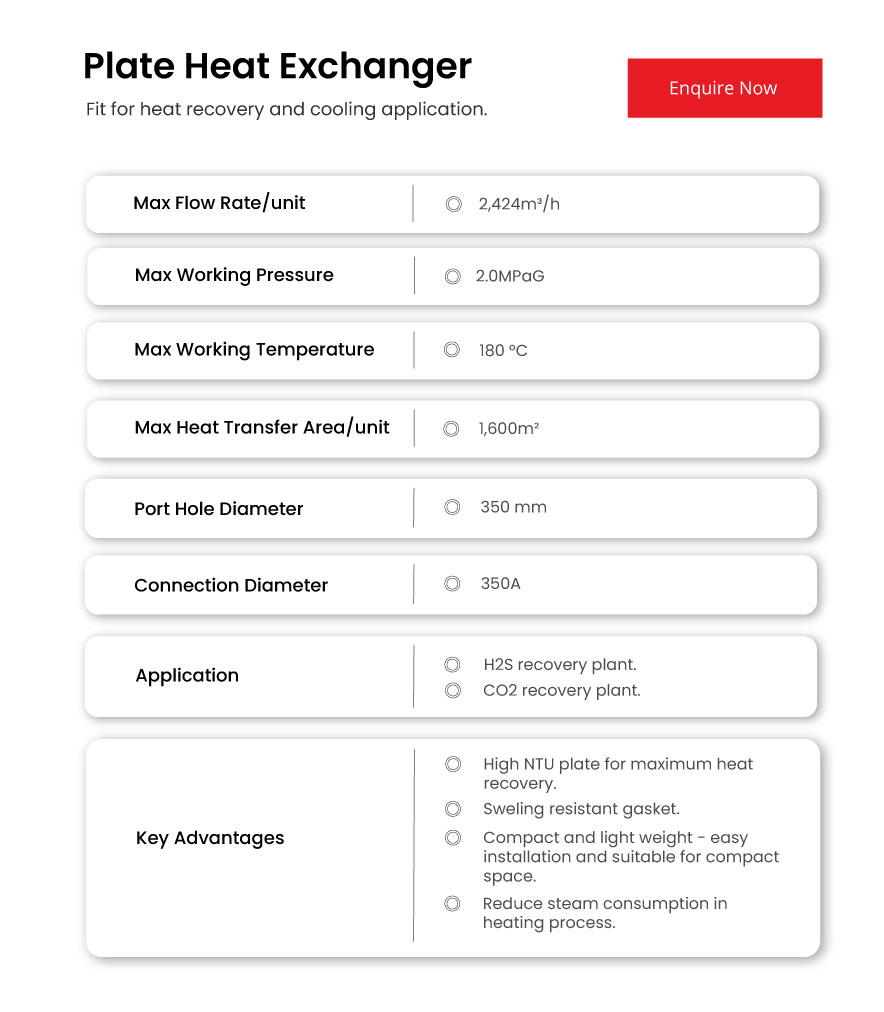

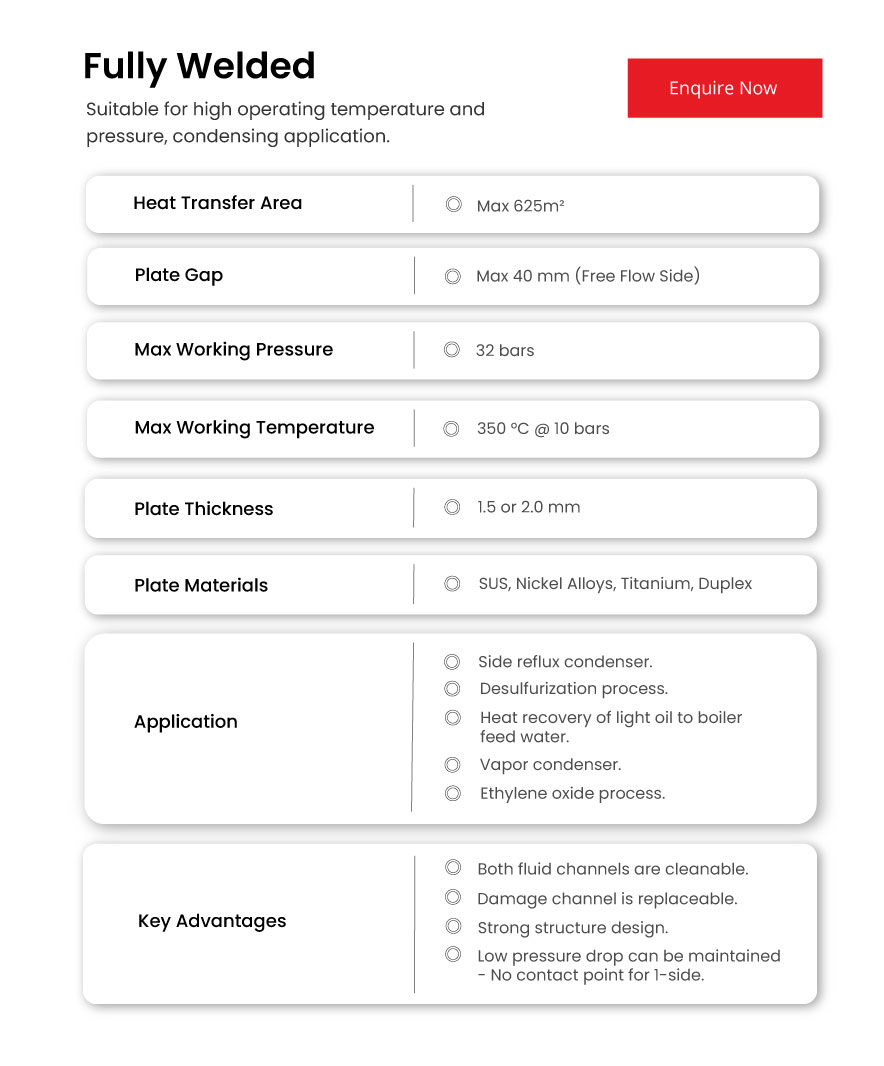

Best Lean Rich Amine Heat Exchanger from Hisaka

Hisaka's SX-80 series is the ideal plate heat exchanger for this application, as it is specially designed for the CO2 recovery process.

The gasket's unique design, which is made of a special composition, ensures that it lasts longer and has a greater gasket life than previous generations. In addition, the new advanced plate corrugation pattern can improve heat transfer performance. As a result, SX-80 can save the maintenance cost, shorten the plant’s downtime, minimise energy consumption, and ultimately maximise productivity.

Hisaka Works has supplied a number of Plate Heat Exchangers at gas refinery plants where amine solutions are used.

Lean Rich Amine Heat Exchanger Features (SX-80 Series)

Plates

Our SX-80 series uses plate design with higher NTU in the Lean/Rich Amine heat recovery. These plate series are intended to provide the best heat transfer capability with the smallest pressure drop possible.

Rich amine is heated up in order to release CO2 gas and lean amine is cooled down to capture CO2 gas circulating between two towers. Rich and lean amine helps each other to cool down or to heat up, which significantly reduces steam consumption at the Regeneration Tower and vice versa, less water is needed to cool down lean Amine at the Absorption Tower. The SX-80 series is the first to offer such maximum energy savings through the use of the tiniest Plate Heat Exchangers. Our SX-80 series also comes with a wide range of plates to adapt its form to every condition. The SX-80 series has a special gasket sealing groove design that helps to maintain gasket sealings even when an amine solution expands gaskets.

Gaskets

Robustness to amine solutions and higher temperature resistance at approximately 130°C during CO2 regeneration (desorption) are both desirable features for Lean/Rich Amine Heat Exchanger gaskets. The most efficient gasket materials are utilised in our SX-80 series gaskets for more consistent sealing performance.

In short, utilising Hisaka’s lean rich amine heat exchanger enables for a huge operational cost savings due to the lower steam consumption required to heat up solutions at the Regeneration Tower and reduced maintenance requirements owing to consistent gasket seal performance.

.jpg)

.jpg)

SX-80

SX-80 LX-90

LX-90

HXC

HXC HXE

HXE

KSH-1H

KSH-1H KSH-1V

KSH-1V KSH-2V

KSH-2V

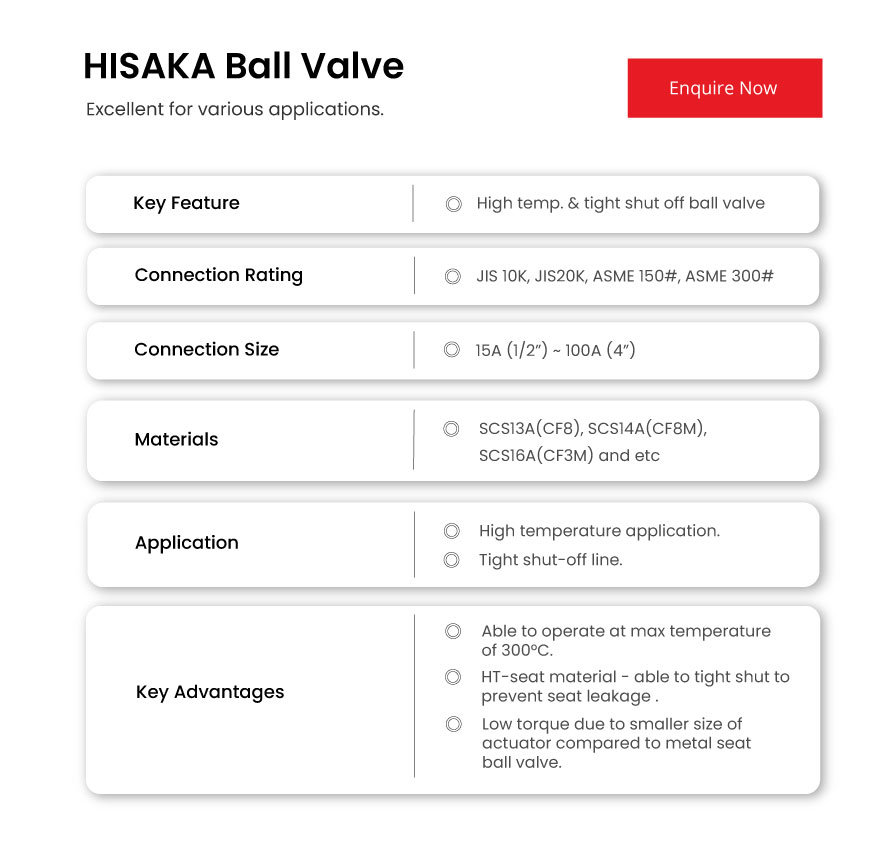

HF5-HT

HF5-HT HF5-M1

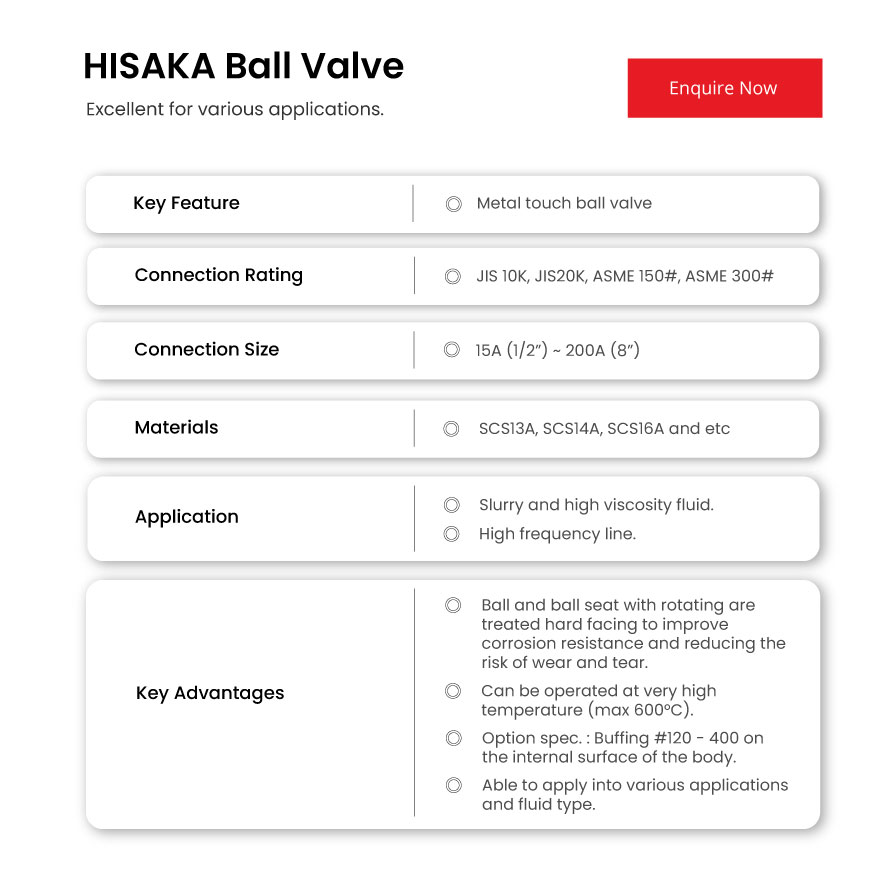

HF5-M1 HJ5

HJ5

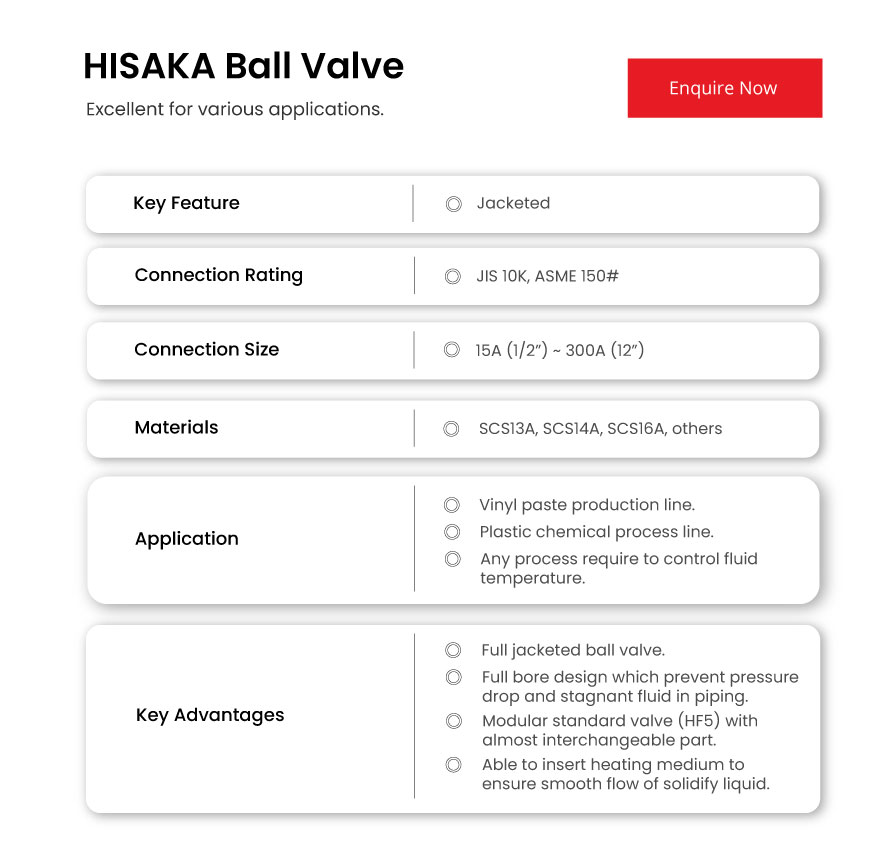

HY1,HY2

HY1,HY2 HY1M,HY2M

HY1M,HY2M