We Here To Help !

Our Suggestion On Common Maintenance Issues

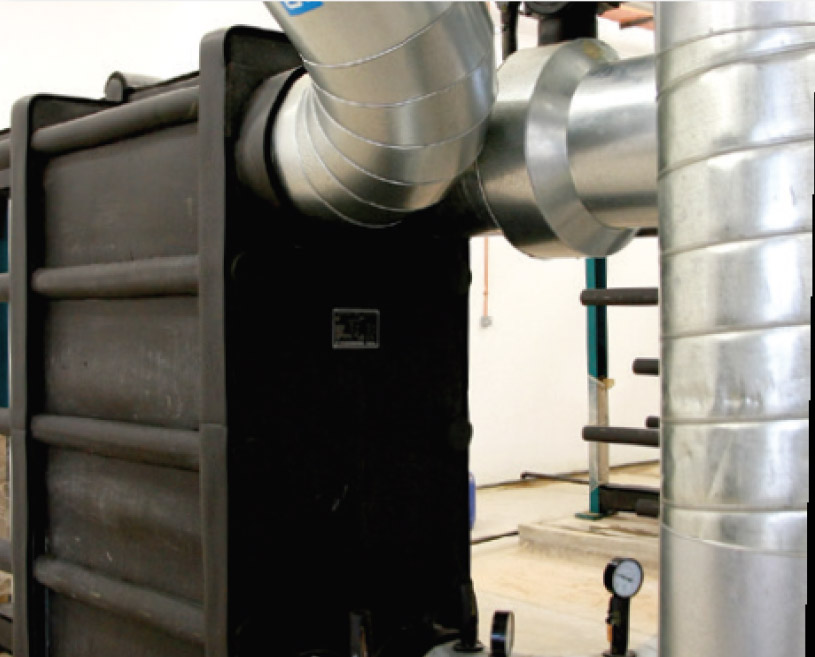

Issue 1: Rusty frames

This issue is occurred due to the heat exchanger has been operated for a long period of time without proper insulation on essential parts. Condensation that happened on the frames can cause rusting, if do not conduct preventive maintenance, bolts and nuts may be damaged.

HISAKA suggestions:

- Insulate the main parts of the heat exchanger with proper material.

- Replace rusted bolts and nuts.

- Proper planning of preventive maintenance to extend heat exchanger lifespan.

Issue 2: Water sedimentation fouling

This issue occurred due to the water used for the plate heat exchanger contains salt (CaCO3). After a long period of operation, salt will start accumulating on the plate which caused fouling. As the plate start to foul, the heat transfer efficiency of the plate heat exchanger will drop.

HISAKA suggestions:

- Conduct periodic maintenance to prevent hard scaling.

- Regular monitoring of outlet pressure and temperature to comprehend the internal condition of PHE.

- Prepare spare plate pack for routine maintenance to reduce downtime.

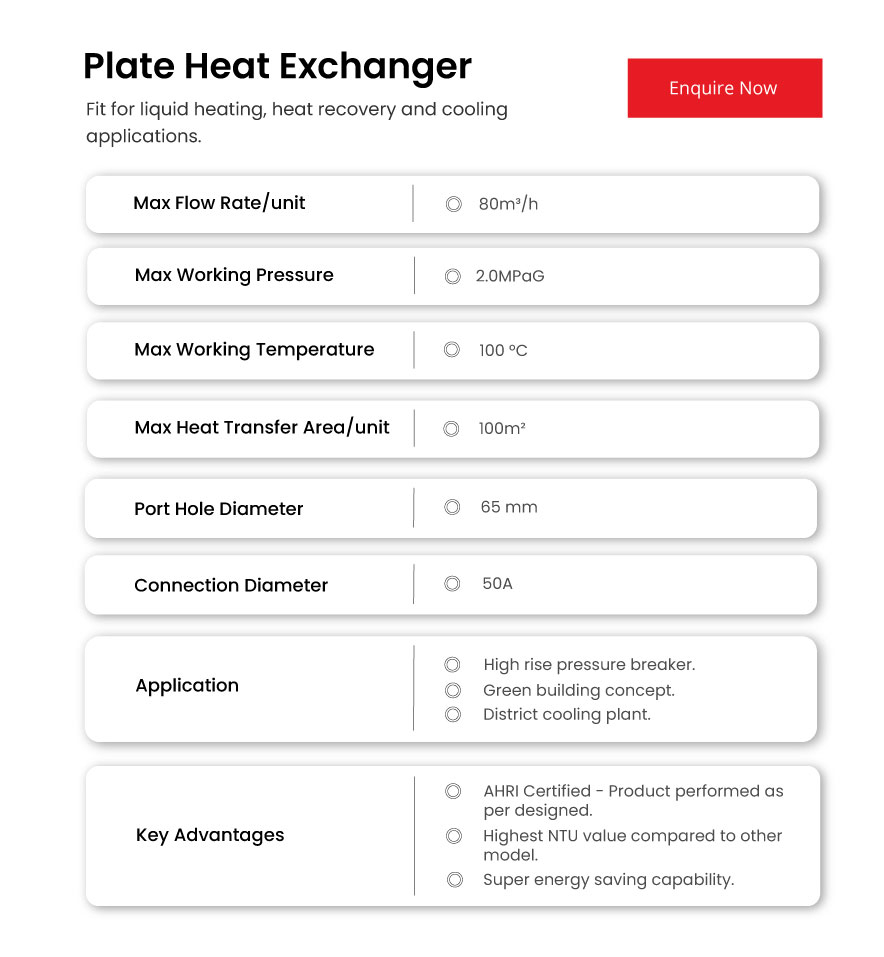

SX-10

SX-10 SX-20

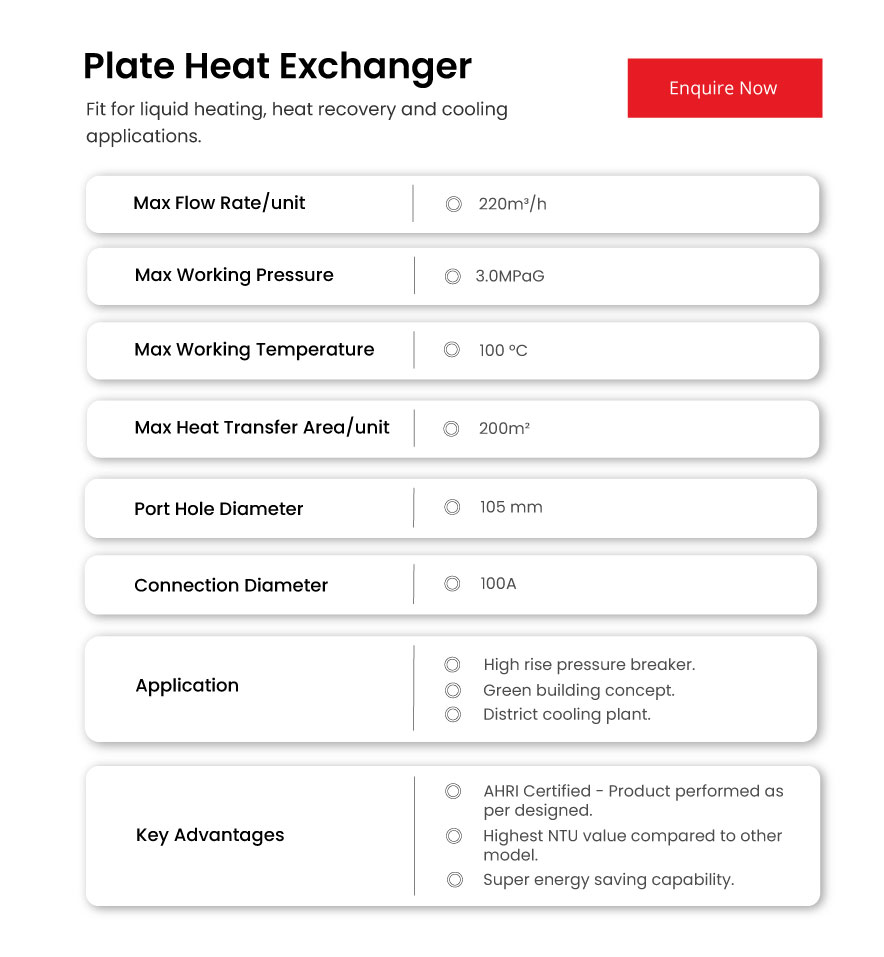

SX-20 SX-30

SX-30

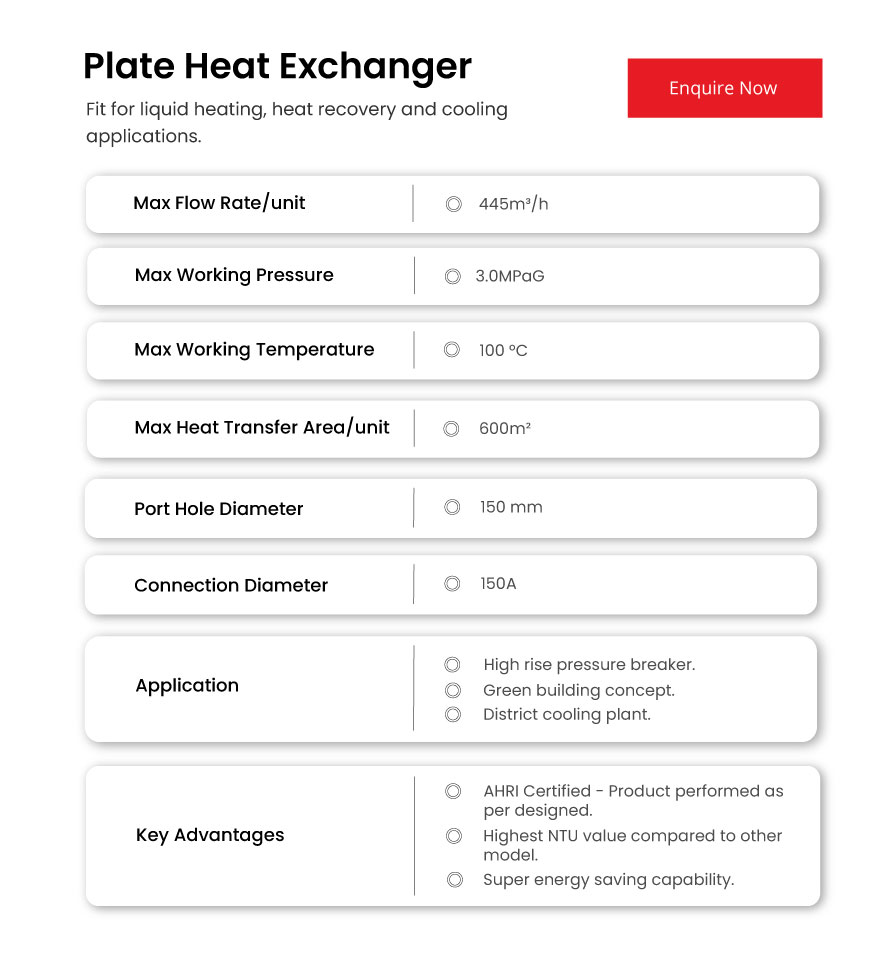

BX-50

BX-50

FM5-LT

FM5-LT HF5-LB

HF5-LB